Article

DMG MORI Legacy Machines: The Sweet Spot Between Price and Performance

In a market flooded with shiny new CNC machines and flashy digital dashboards, there’s still a quiet truth most experienced machinists know: the best-performing machines on the floor are often the ones built 15–25 years ago.

The early DMG MORI and Mori Seiki models—engineered in Japan and Germany during the late 1990s through the 2000s—represent the perfect balance between mechanical rigidity, reliable electronics, and long-term value.

At Protech Machine Tool Sales, we’ve built our reputation around these proven legacy machines. Because when it comes to performance per dollar, nothing else even comes close.

The Evolution of DMG + Mori Seiki

Before they merged,

Mori Seiki and

Gildemeister (DMG) were already two of the most respected names in precision machining.

Mori Seiki was known for its rock-solid turning centers and bulletproof horizontal mills, while DMG brought high-speed European innovation and advanced multi-axis control.

In the early 2000s, the two companies began collaborating—sharing engineering resources and merging product lines. That partnership eventually became the unified DMG MORI brand, combining Japanese reliability with German precision.

The result was a new generation of CNC machines that could run complex, high-precision parts with incredible consistency—and that generation is exactly where Protech’s inventory shines.

Why Legacy DMG MORI Machines Are Still Elite

Modern CNCs have more software layers and touchscreen gadgets, but the core performance still comes from the same fundamentals: rigidity, control, and mechanical balance.

That’s where early DMG MORI machines excel.

1. Overbuilt Castings

Models from this era feature massive box ways and cast iron bases that dampen vibration better than lightweight modern frames. This gives better surface finishes, tool life, and accuracy.

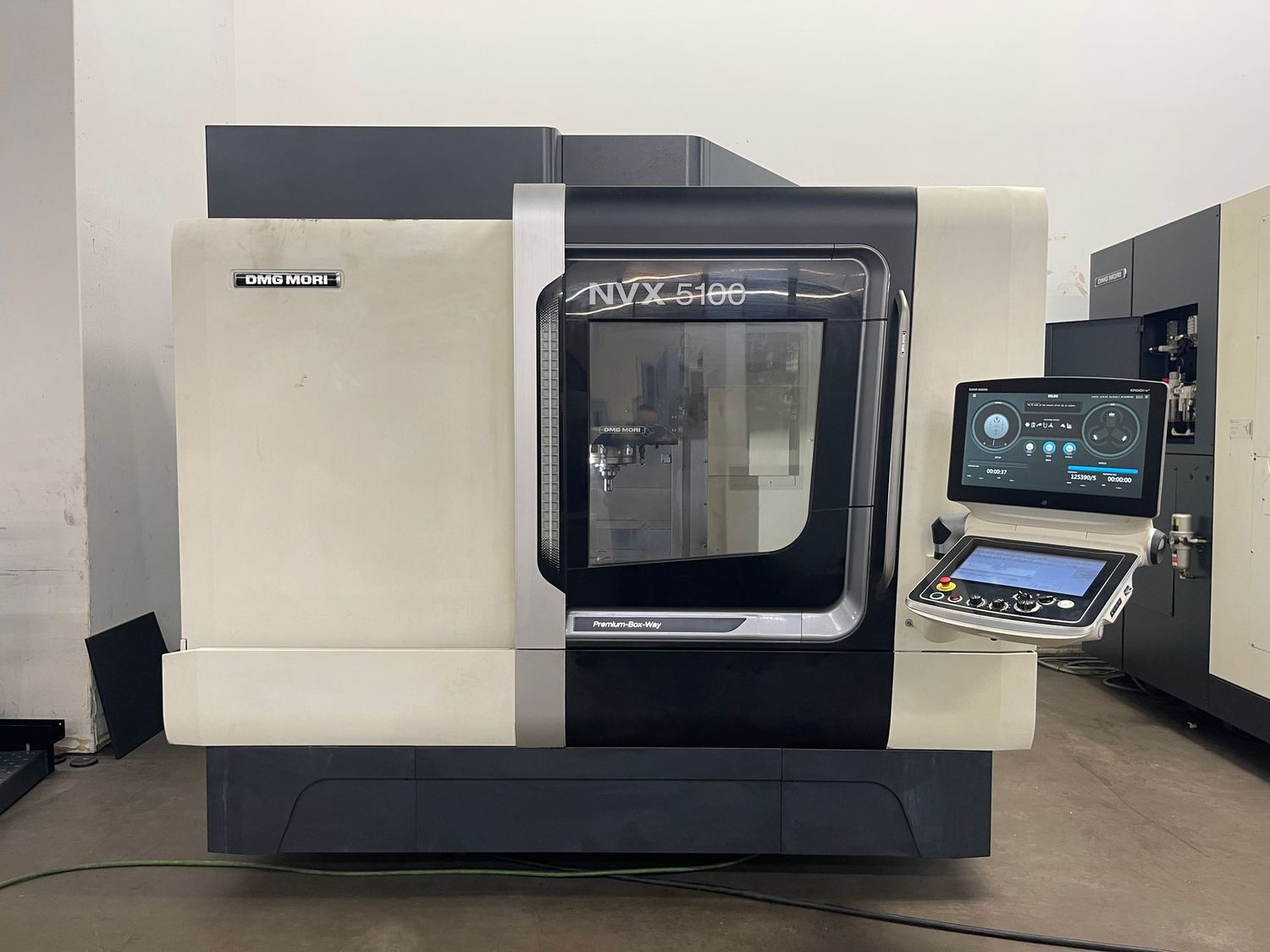

2. Reliable Controls

These machines run Fanuc, MAPPS, or early CELOS interfaces—simple, stable, and fully supported today. You can find replacement parts, experienced technicians, and programming support anywhere.

3. Real-World Proven

Thousands of DMG MORI lathes and mills from the early 2000s are still running daily in production shops, holding tolerances that rival new machines costing three times as much.

When maintained properly—and inspected by a team like Protech—they can easily deliver another decade or more of high-quality output.

Top DMG MORI Legacy Models That Hold Their Value

Here are a few model families from the late 1990s and 2000s that still dominate the used market:

NL / NLX Series

Heavy, accurate, and versatile turning centers that combine raw rigidity with modern live-tool capability. Ideal for small and mid-batch production.

NH / NHX Series

Palletized horizontal machining centers with excellent chip evacuation and uptime. Perfect for multi-shift environments and repeat production.

DMU 50 / 65 / 80

Compact 5-axis mills that brought complex machining to small footprints. A favorite among mold makers and aerospace job shops.

SL and ZL Series

The backbone of many machine shops—reliable, straightforward lathes that can cut for decades with proper care.

Each of these models has stood the test of time, both mechanically and financially. They remain among the most sought-after used CNC machines in the market, precisely because of their reputation for reliability and accuracy.

The ROI Advantage: Precision Without the Price Tag

A new 5-axis or turning center can easily cost $300,000 to $600,000—and that’s before tooling, setup, and training.

A clean, well-maintained DMG MORI from the early 2000s can deliver 80–90% of that same performance for a fraction of the investment.

It’s a simple equation: less depreciation, proven reliability, faster ROI.

That’s why smart shop owners, job shops, and small manufacturers are adding legacy DMG MORIs to their floors instead of taking on expensive equipment financing.

Why Protech Is the Go-To Source for Used DMG MORI

Buying a used CNC machine can be risky—unless you buy from a team that knows exactly what to look for.

At Protech Machine Tool Sales, we’ve spent years specializing in the inspection, testing, and sale of DMG MORI and Mori Seiki machines. We know their strengths, we know their quirks, and we know what separates a great machine from a worn-out one.

Here’s how we do it:

- Hands-on inspections: Every machine is powered on, warmed up, and tested before sale.

- Full mechanical evaluations: We check backlash, spindle vibration, axis noise, and lubrication systems.

- Documentation: Buyers receive detailed photos, specs, and service information.

- Nationwide logistics: We coordinate rigging, transport, and setup—so you can start cutting fast.

- Post-sale support: Need help getting up and running? We’re here for it.

When you buy a used DMG MORI from Protech, you’re not getting a blind auction machine—you’re getting a proven piece of precision equipment, verified by experts.

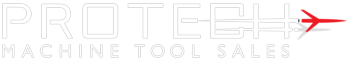

Inventory Highlight: DMG MORI Machines Ready for Delivery

Below are examples of the models we often carry, inspect, and prepare for immediate sale:

- DMG MORI NLX 2500SY – Sub-spindle, Y-axis, and live tooling

- Mori Seiki NH4000DCG – Horizontal machining center with pallet changer

- DMG MORI DMU 50 – Compact 5-axis milling center

- Mori Seiki SL-253B – Classic turning center with rock-solid repeatability

The Bottom Line

The machines that built reputations in the CNC industry didn’t come from cutting corners—they came from engineering excellence.

DMG MORI’s legacy machines represent that philosophy better than anything else on the market: strong, precise, and built to last.

At Protech Machine Tool Sales, we bring that legacy back to life—testing, inspecting, and delivering machines that are still ready to earn.

If you’re ready to add proven DMG MORI performance to your floor without the sticker shock of new equipment, browse our inventory today or contact us to schedule an inspection or demo.