Article

Why 1990s and 2000s Mori Seiki Machines Still Outperform Newer Imports

Some of the most reliable CNC machines on the floor today were built before smartphones existed.

In an era when manufacturers are cutting corners on castings, controls, and component quality, the legendary Mori Seiki machines of the 1990s and early 2000s still set the standard for precision and durability.

If you’re looking for a CNC lathe or machining center that can cut tight, run nonstop, and stay accurate year after year, you don’t need to buy new—you need to buy used Mori Seiki.

And that’s exactly what we specialize in at Protech Machine Tool Sales.

Built When Iron Mattered

There’s a reason machinists who’ve been in the trade for decades still trust older Mori Seikis.

Machines like the

SL,

ZL,

CL, and early

NL series were built with massive cast iron bases, oversized ball screws, and industrial-grade components designed to last for decades, not just warranty periods.

The design philosophy was simple: rigidity equals precision.

When a machine is overbuilt, you can take heavier cuts, achieve better finishes, and hold tolerance day after day—even after 20+ years of service.

Many of these older Mori Seiki machines were made in Japan during the company’s “golden age” of manufacturing. That era’s quality control, assembly tolerances, and material standards were second to none.

The result? Machines that still outperform many brand-new imports built to hit a price point instead of a precision target.

Proven Accuracy, Decades Later

Mori Seiki’s precision didn’t come from marketing—it came from engineering.

Models from the 1990s and early 2000s used

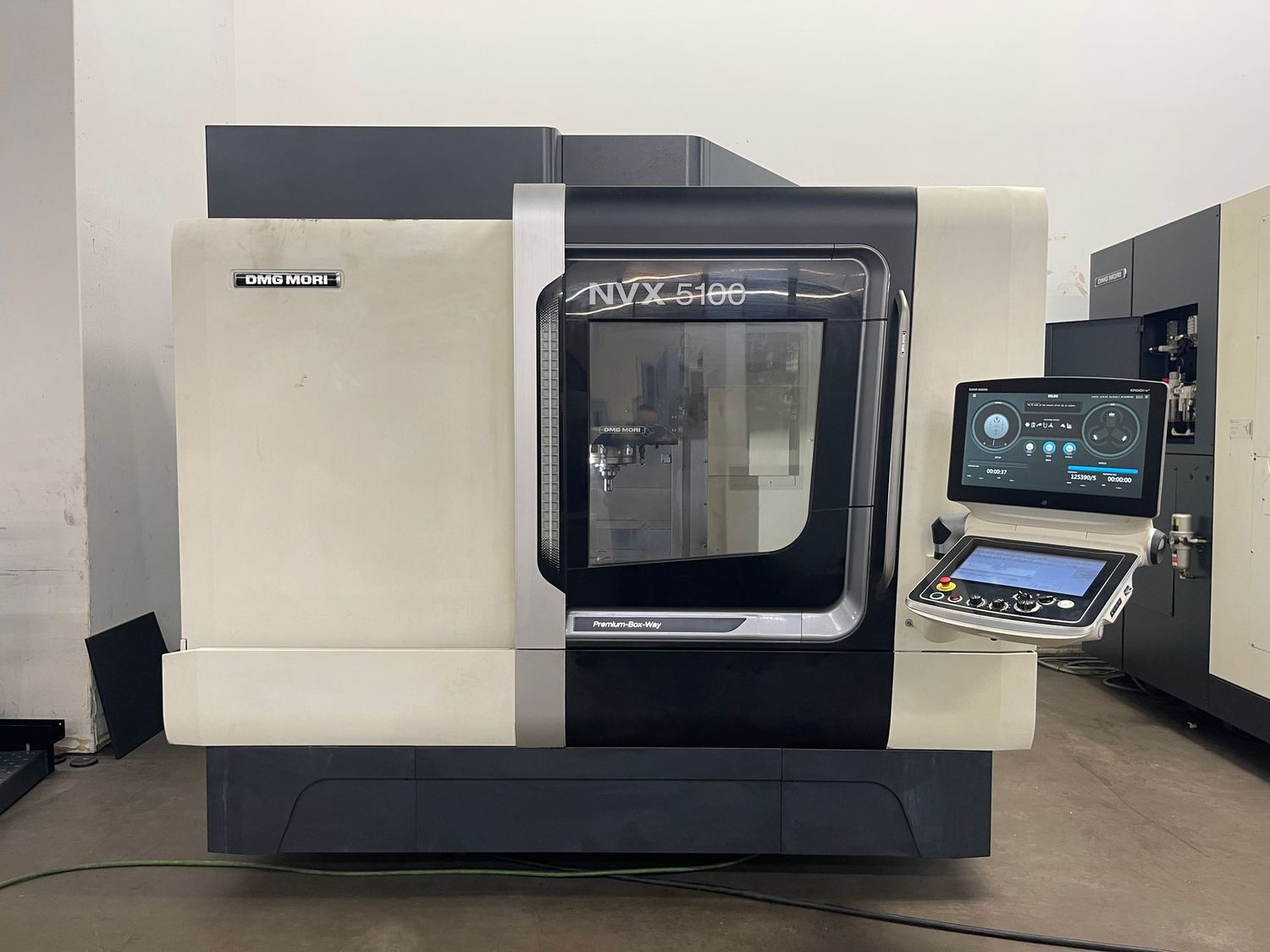

Fanuc-based MAPPS controls, which are still widely supported and extremely stable. The electronics are straightforward, the diagnostics are clean, and the interface is intuitive for operators who actually run parts—not just program on paper.

Thousands of these machines are still holding 0.0002” (two tenths) tolerances every day in toolrooms and production shops across the country.

The secret is the combination of heavy castings, accurate ball screws, and robust servo systems that never relied on fragile consumer electronics.

Even better, these machines have predictable failure patterns and easy parts availability. You can still order spindles, encoders, bearings, and even control boards from Fanuc, Mori, or third-party suppliers. That’s what makes a used Mori Seiki such a smart long-term investment.

Easy to Maintain, Easier to Afford

Modern CNCs are impressive, but they also come with touchscreens, proprietary software, and service contracts that can cost as much as the machine itself.

Meanwhile, older Mori Seikis are straightforward, mechanical, and built to be serviced.

You don’t need factory technicians with special passwords—any experienced CNC tech can keep them cutting.

From a financial standpoint, the math is simple.

A new lathe or mill can easily cost $250,000–$500,000 and depreciate 40–50% in five years.

A clean, well-maintained

Mori Seiki from the early 2000s can deliver the same level of precision and throughput for a fraction of that price—often 10–20% of the original cost.

At that price, a used Mori Seiki isn’t just a tool—it’s an opportunity to grow your capacity without taking on massive overhead.

Why Protech Is the Safe Way to Buy Used Mori Seiki

Buying used machinery doesn’t have to be a gamble.

At

Protech Machine Tool Sales, we make sure every Mori Seiki or DMG MORI machine we sell is one we’d put on our own floor.

Here’s how we do it right:

- Powered-on inspections: Every unit is test-run and evaluated under load, not just jogged.

- Spindle and axis checks: We check backlash, spindle temperature, and smoothness across the entire range.

- Clean documentation: You’ll know what’s been replaced, serviced, or rebuilt before you buy.

- Turnkey support: From rigging and transport to installation and calibration, we handle the details.

- Financing options: We make it easy to get the machine you want without tying up capital.

When you buy from Protech, you’re not buying a mystery—you’re buying a verified, production-ready machine with real history and real support.

What to Look for in a Used Mori Seiki

If you’re considering one of these older machines, here’s what to focus on:

- Spindle condition – Listen for bearing noise and test under warmup.

- Axis backlash – Should be minimal, with consistent readings across travel.

- Ball screw and ways – Check for wear marks or inconsistent movement.

- Control health – Ensure the Fanuc or MAPPS interface boots cleanly and all I/O functions are operational.

- Cut test results – The best proof of quality is seeing chips fly.

If you’re not sure what to look for, Protech can handle the full inspection for you—before you commit to anything.

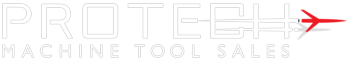

Inventory Spotlight: Ready-to-Run Classics

Below are examples of the Mori Seiki and DMG MORI machines we frequently stock and refurbish:

- Mori Seiki SL-25 / SL-253B: Heavy-duty 2-axis turning centers built for production.

- Mori Seiki NL-2000SY / NLX-2500: Y-axis, sub-spindle, and live tooling for multi-operation work.

- Mori Seiki NH4000DCG: Horizontal machining center with pallet changer and incredible uptime.

- Mori Seiki NV5000 / NVX5100: Compact vertical machining centers ideal for precision milling.

The Bottom Line

When you invest in a

used Mori Seiki, you’re not buying old technology—you’re buying proven craftsmanship.

These machines were built when engineering came first and shortcuts didn’t exist.

At Protech Machine Tool Sales, we bring those machines back to life and deliver them ready to cut—tested, inspected, and fully functional.

If you’re ready to add proven Japanese precision to your shop floor without breaking the bank, browse our current Mori Seiki and DMG MORI inventory or contact us today to schedule a demo or inspection.